Actions

To achieve the main objectives, the Project involves different actions:

B. IMPLEMENTATION ACTIONS

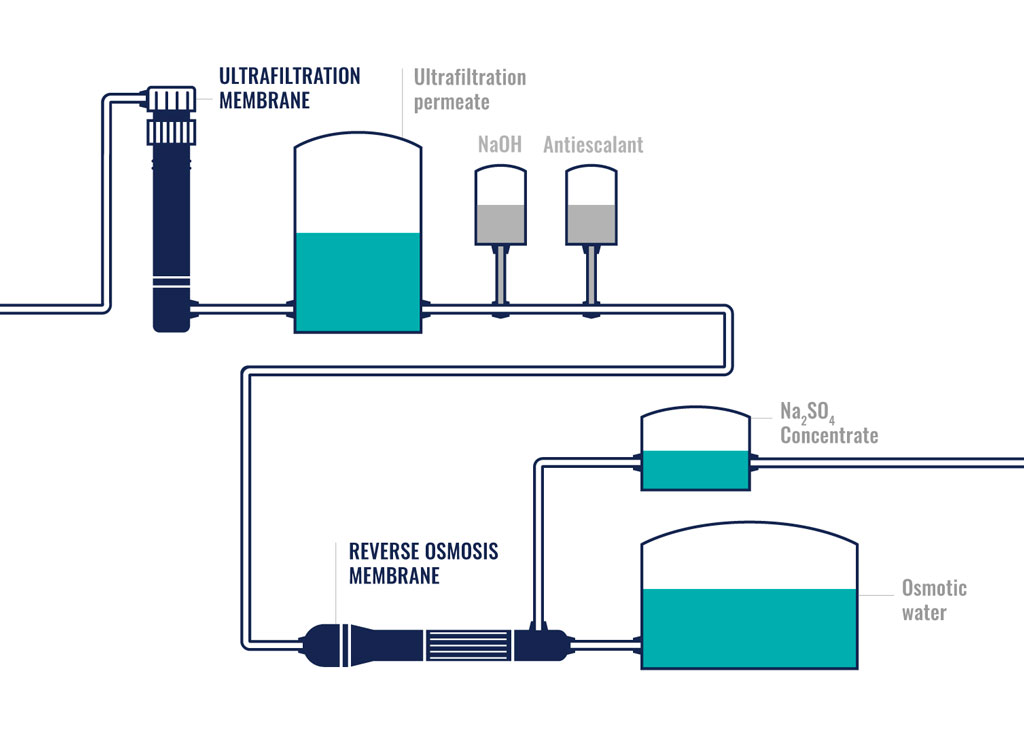

B1: Design and construction of the osmosis preindustrial pilot installation

Based on the results obtained in the H2020 ZeroBrine project, an industrial ultrafiltration pilot equipment and reverse osmosis pilot equipment will be designed and built with a treatment capacity of 40 m3/h of precipitated silica brines.

B2: Technological validation and optimization of the reverse osmosis process

The process will be optimized to obtain the maximum performance of effluent permeated with the quality to be used as process water (< 500 µS/cm) and a concentrated effluent with a minimum content of 120 g/L of sodium sulphate. In addition, both ultrafiltration and reverse osmosis membrane cleaning cycles will be optimized for the proper operation of the installation. Finally, their service life will be validated. Own use in precipitated silica process of concentrated brine will be studied to substitute raw materials.

B3: Analysis of operating costs of the concentration process via reverse osmosis: economic viability of the technology

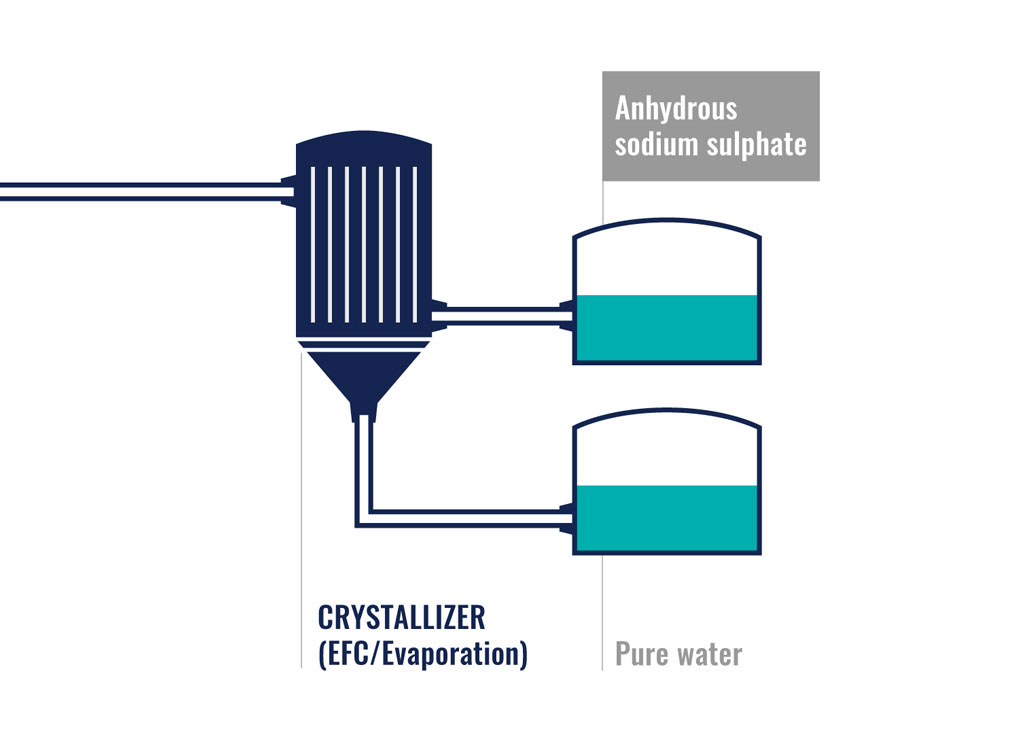

B4: Technological validation and optimization of evaporation and crystallization of anhydrous sodium sulphate

B5: Customer validation of anhydrous sodium sulphate

Once the anhydrous sodium sulphate has been obtained, samples will be sent to potential future customers. They will carry out an approval and validation of the product for the potential introduction in the market at the different sectors in which it could be used.

B6: Analysis and study of technology transfer to other chemical processes and/or industrial sectors

Candidate industries to have similar effluents have been already identified and will be contacted (textile, chemical, pharma, etc.) to provide composition and samples of their effluents. The treatment scheme will be firstly evaluated at bech-scale in the EURECAT’s branch of the Brine Excellence Centre established in H2020 ZEROBRINE project. Those more promising effluents will be selected for a short in-situ pilot scale study using an existing pilot plant. Experimental design and results evaluation will be done to evaluate technical, environmental, and economic feasibility of a full-scale installation. Results will be transfer to authorities and reference documents.

B7: Market uptake - Business plan

With all gathered data during the project, a market study will be carried out for the revaluation of the anhydrous sodium sulphate obtained. Initial idea is to find a win-win business model with primary sulphate extractors so the product can be benefited by their commercial and distribution network. An exploitation plan will be defined for the design of an installation with a treatment capacity of 120 m3/h. Replication and transfer plan will be generated. Patentability will be studied.

C. MONITORING OF THE IMPACT OF THE PROJECT ACTIONS

C1: Sustainability monitoring and evaluation

Oversee of the project sustainability by the evaluation of the environmental (LCA) impact and performance of a socio-economic assessment of treatment scheme and its effect on the local economy and population. Calculation of Water Footprint. Environmental risk Assessment Study.

C2: KPI monitoring

Monitoring and measurement of the identified project performance indicators to quantify the impact of the project on the environmental problem targeted.

D. PUBLIC AWARENESS AND DISSEMINATION OF RESULTS

D1: Dissemination and public awareness of results

E. PROJECT MANAGEMENT

E1: Project management and coordination

Management and coordination of the project execution will be held to achieve the overall project objective within time and budgetary limits. IP management with a possible patent filling will be carried out. AFTER LIFE plan will be generated.